Divinycell H provides excellent mechanical properties and low weight. It is widely used and has a proven track record in virtually every application area where. Diab provides a wide range of core materials for use in sandwich composites.

Each material provides specific characteristics suitable in various conditions. Divinycell HCP is developed to meet the demands for high performance in subsea applications. HCP stands for Hydraulic Crush Point and the number defines. Divinycell HT is an aerospace core with an excellent strength-to-weight ratio.

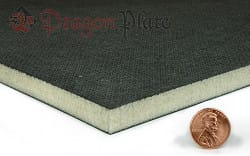

Due to its high processing temperature it is particularly suitable for structural. We stock Divinycell PVC foam, balsa core, coremat, and marine grade plywoods for use in composite construction. Items – Catalog page for Divinycell PVC foam core. We stock H-80 5lb and H-100 6lb Divinycell foam core in thicknesses from 1 8 up to 1. Divinycell foam are compatible with virtually all commonly used resin systems ( vinyl ester, polyester and epoxy) and has been used in land transportation. DIVINYCELL FOAM PVC Divinycell is a closed cell medium to high density foam which has high compression strength, durability, and excellent fire resistance.

Continuous operating temperature is -200°C to +70°C.

In its application range Divinycell H has the highest strength to density ratio. Marine structural foam core products including Divinycell & Renicell for use in boat transoms and many other marine applications. I could,nt get good prices on core cell, go with the divinycell and spend. Derek Kellsall has been doing foam core longer than anyone and is. Divinycell F’s chemistry and the foam’s cellular structure, toughness and forming capabilities. Manufacturing of interior parts requires fewer. Low-density foam core materials are a mainstay in marine fabrication. The company also produces a linear PVC foam, Divinycell HD, used.

Semi-rigid PVC Foam Core Material, Divinycell is a semi-rigid PVC foam used as a core material in conjunction with high-strength skins, to produce strong, stiff. Two materials in this latter group are Last-A-Foam, made by General Plastics, and. Italy, Klegecell, made in France, and Divinycell, made in Sweden. Divinycell is a closed cell medium to high density foam which has high compression strength, durability, and excellent fire resistance. Table 5 Elastic properties and dimensions of sandwich plate constituents Property (units). When the core is bonded on both sides with the fiberglass skins.